At N.G.P Tobacco ApS, we take pride in overseeing every stage of our production process, ensuring the highest standards of quality and consistency. Unlike many manufacturers, we own the rights to our products and are actively involved from start to finish—beginning with the precise formulation of our unique blends, through production and packaging, all the way to the final product delivered to consumers.

Operations

Full Production Oversight

Rigorous Quality Control

Our rigorous quality control process guarantees that every nicotine pouch meets strict industry regulations and exceeds customer expectations. By maintaining full control over our manufacturing, we uphold our commitment to excellence, ensuring that each product reflects the superior craftsmanship and innovation that define our brands.

Supply Chain Management

We collaborate with a carefully selected network of responsible and trusted suppliers to ensure the highest quality and safety standards for our ingredients. Each year, we conduct a comprehensive supply chain review to verify that all suppliers continue to meet our stringent requirements, allowing us to maintain seamless production and timely delivery.

By prioritizing efficiency and reliability, we minimize production downtime and ensure that every order is fulfilled promptly—delivering fresh, high-quality products to our clients. Additionally, we adhere to strict regulatory compliance, with all ingredients meeting the EU’s Tobacco Products Directive (2014/40/EU) and other relevant safety standards. Our commitment to using only approved and safe ingredients reinforces our dedication to excellence in every nicotine pouch we produce.

Hygiene and Manufacturing Facility Standards

Manufacturing facilities adhere to strict hygiene standards to ensure the production of safe and sanitary products. We perform these tests regularly to ensure the protection of our products and their safety.

Testing and Quality Assurance

At N.G.P Tobacco ApS, quality assurance is embedded into every stage of our production cycle—from the sourcing of raw ingredients to the final testing of our blends in our state-of-the-art in-house laboratory. We conduct rigorous quality control on our formulations, ensuring consistent pH levels, ingredient composition, and recipe precision across every batch.

Our dedicated quality department performs daily inspections and extensive testing on our production lines, maintaining the highest industry standards. In addition, we are committed to Corporate Social Responsibility (CSR), continuously optimizing our processes to minimize our environmental impact while adhering to all local regulations.

Certification and Compliance

We are in the final stages of obtaining ISO 9001:2015 certification, demonstrating our commitment to exceptional quality management. Additionally, our Good Manufacturing Practice (GMP) certification is currently in progress and is expected to be completed by 2025, further ensuring the highest standards of safety, consistency, and product excellence.

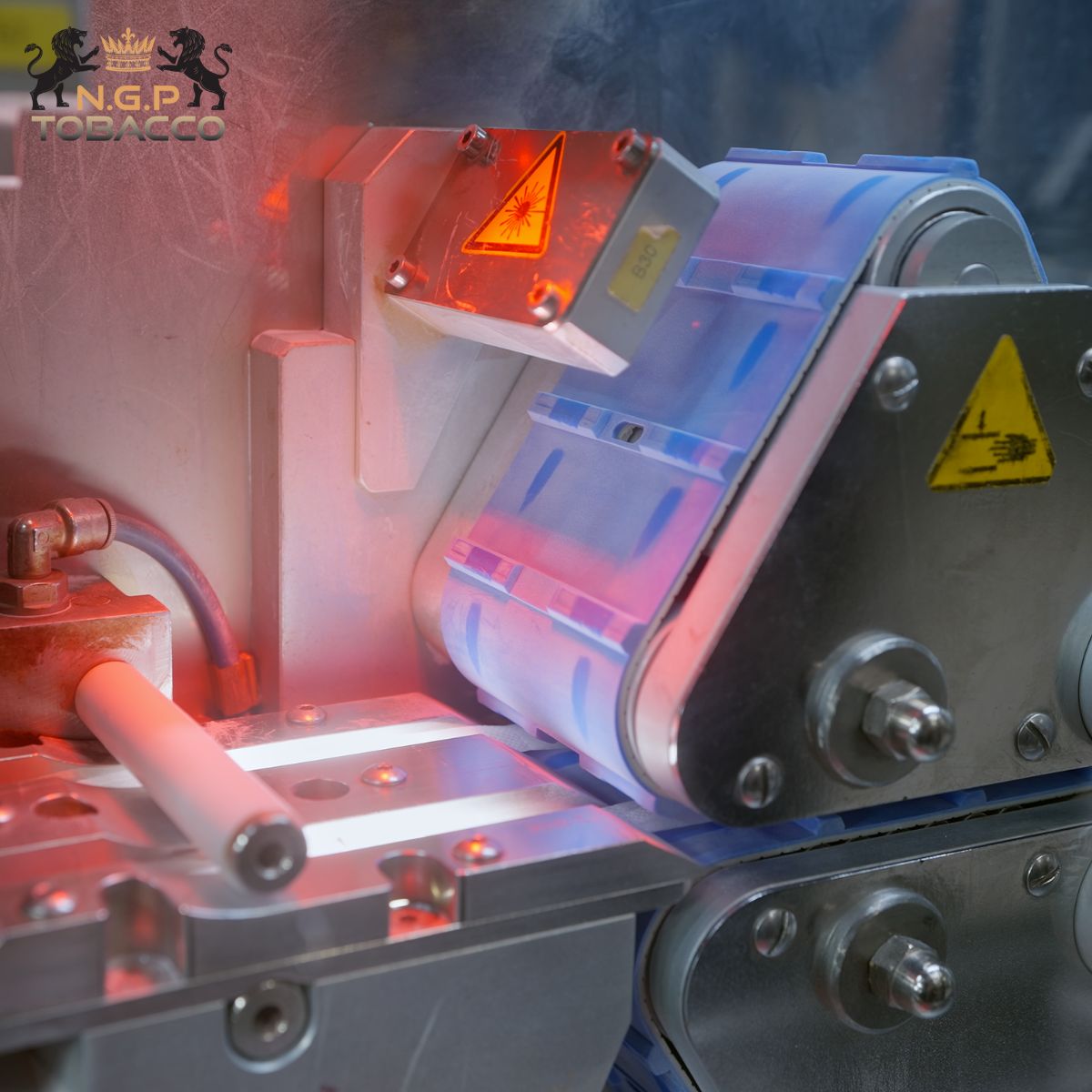

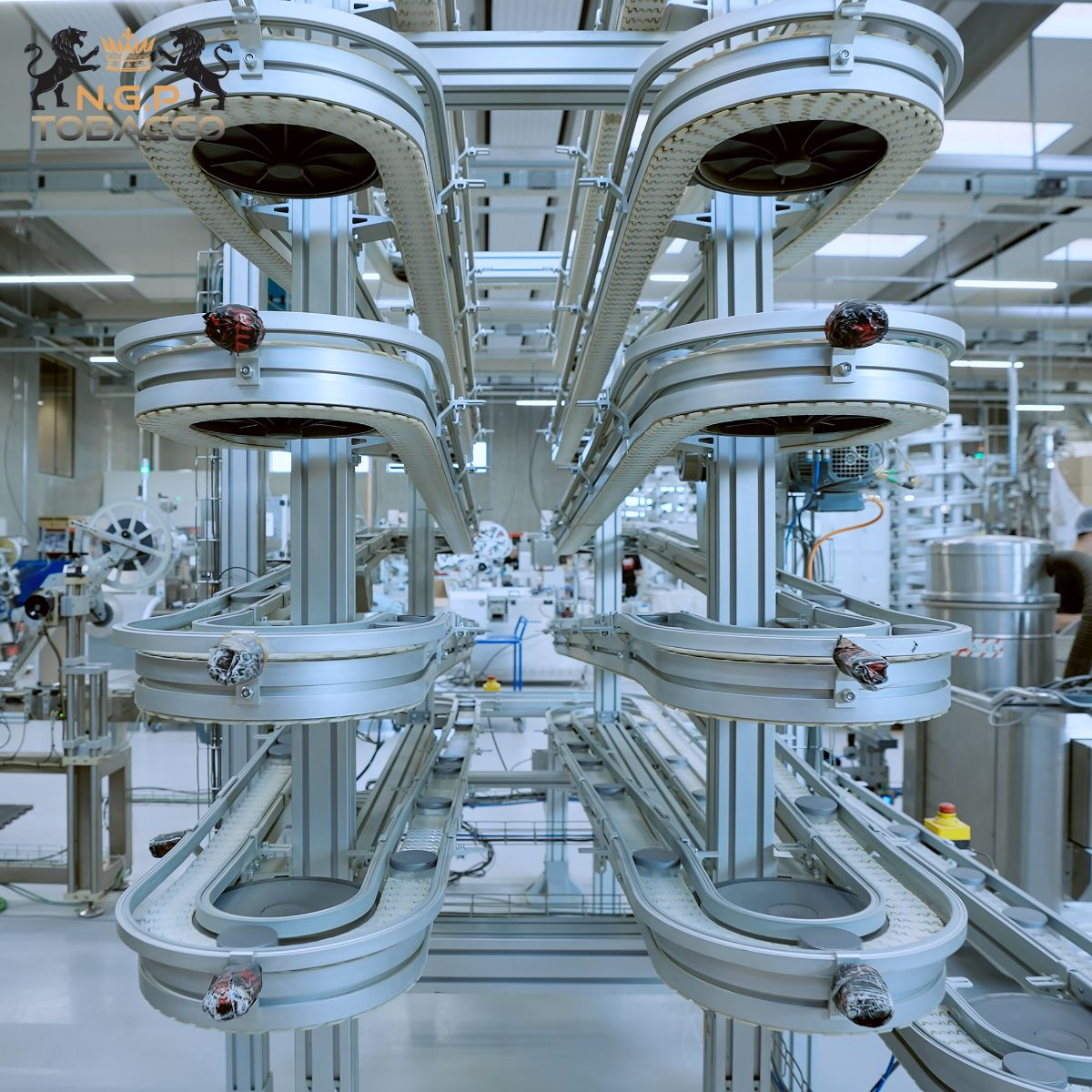

MANUFACTURING MACHINERY

N.G.P Tobacco ApS manufacturing facilities in Denmark. We actively use modern machines, think about our use of water, and recycle in order to limit our imprint.

Manufacturing

G.D is the world’s leading supplier of high-tech machines for cigarette making and packing, filter production, and other tobacco-based and next-generation products.

Thanks to its extremely extensive machine range, G.D is the only manufacturer producing complete high speed lines and a wide range of solutions for the tobacco industry. G.D Headquarters, with its worldwide subsidiaries and service centers, provides an extensive sales and service network, always close to clients.

Machinery used for nicotine pouches production in N.G.P Tobacco ApS factory by G.D S.p.A is certified and verified according to the following

ISO certification, 450001:2018, 9001:2015.

PACKAGING & ORDERING

PALLET

- Each pallet contains 96 cases

CASE

- Each case contains 18 rolls

ROLL

- Each Roll is composed of 5 cans

This structured operation system ensures ease of handling, storage, and order fulfillment.

- Choosing a selection results in a full page refresh.